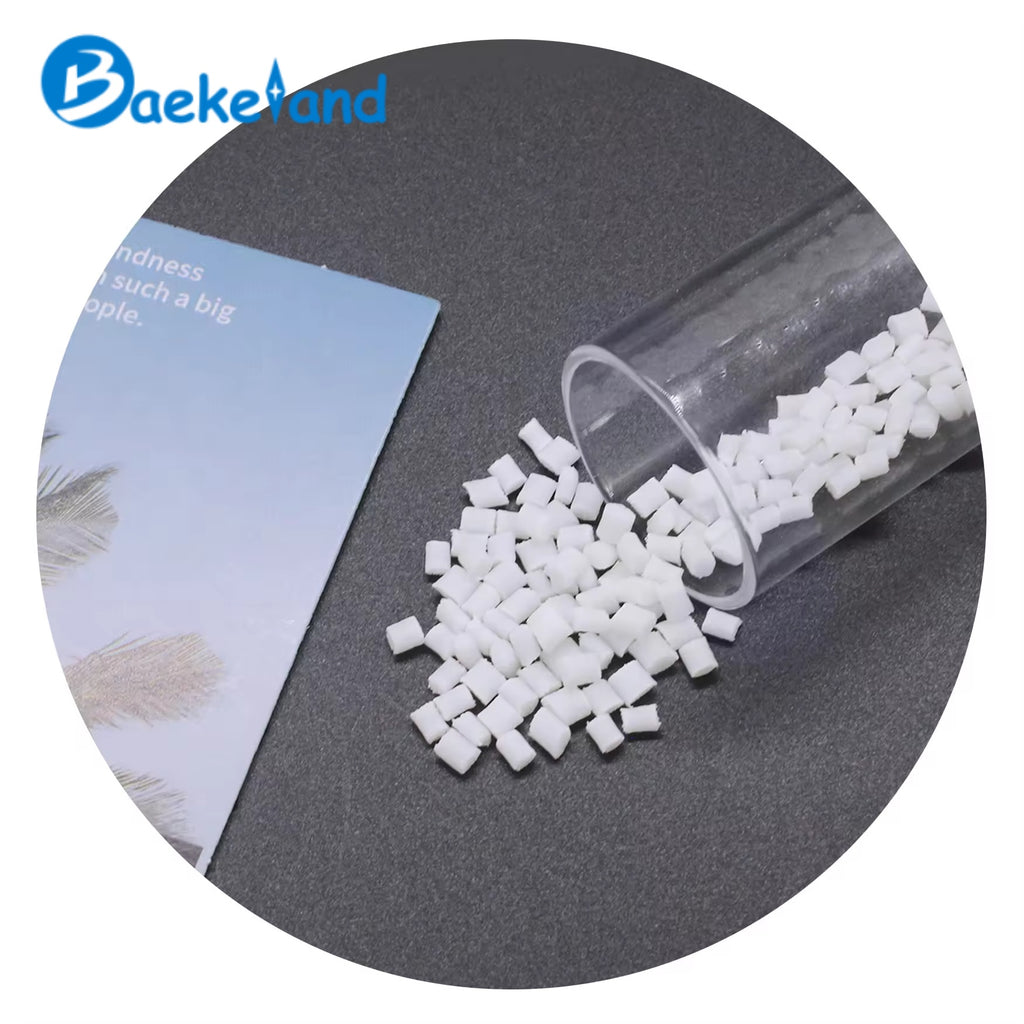

Baekeland (Xiamen) High Performance Modified PET Resin for Automotive Parts, Electrical Components & Packaging Applications

Baekeland (Xiamen) Modified PET (Polyethylene Terephthalate) resin is engineered to provide superior mechanical strength, excellent thermal stability, and enhanced chemical resistance compared to standard PET. Through reinforcement and modification, this PET grade is ideal for high-demand applications including automotive components, electrical housings, and durable packaging.

Key Features

Enhanced Mechanical Properties – Increased tensile strength, stiffness, and impact resistance, especially in glass fiber reinforced grades.

High Thermal Resistance – Suitable for continuous use at temperatures up to 150–170°C.

Excellent Chemical and Hydrolysis Resistance – Resists degradation in humid and chemical environments.

Improved Dimensional Stability – Reduced warpage and shrinkage during processing.

Flame Retardant Options – Available UL94 V-0 certified grades for electrical and safety-critical uses.

Good Processability – Compatible with injection molding, extrusion, and blow molding.

|

Property |

Test Method |

Typical Value (Glass Fiber Reinforced) |

|

Appearance |

Visual |

Natural or black pellets |

|

Density |

ASTM D792 |

1.38 – 1.45 g/cm³ |

|

Melt Flow Index (MFI) |

ASTM D1238 (270°C/2.16kg) |

10 – 30 g/10min |

|

Tensile Strength |

ASTM D638 |

90 – 130 MPa |

|

Flexural Modulus |

ASTM D790 |

5000 – 8000 MPa |

|

Notched Izod Impact |

ASTM D256 |

15 – 25 kJ/m² |

|

Heat Deflection Temperature |

ASTM D648 |

140 – 170°C |

|

Water Absorption (24h) |

ASTM D570 |

< 0.2% |

|

Flame Rating |

UL94 |

V-0 (for flame retardant grades) |

|

Chemical Resistance |

- |

Excellent against oils, solvents, and chemicals |

Applications

- Automotive parts and housings

- Electrical components and enclosures

- Consumer goods and appliances

- Industrial machinery components

- Custom parts through injection molding or extrusion