High Impact Modified PMMA Resin for Automotive Lighting, Displays & Optical Components -Baekeland (Xiamen) New Materials Co., Ltd.

Xiamen Baekeland Modified PMMA (Polymethyl Methacrylate) Resin offers enhanced impact resistance, excellent optical clarity, and outstanding weatherability. Specially engineered for demanding applications, this PMMA grade is ideal for automotive lighting systems, LED light guide panels, optical lenses, and high-end display covers.

PMMA is a high-performance thermoplastic engineered for specific industry needs. Our modified PMMA compounds are enhanced with reinforcements such as glass fiber, impact modifiers, flame retardants, or UV stabilizers to meet demanding application requirements.

Key Features

High Impact Resistance – Modified with rubber or core-shell elastomers for 5–10x the impact strength of standard PMMA.

Excellent Optical Transparency – Light transmittance over 92%, suitable for optical-grade components.

Superior Weatherability – Excellent UV and aging resistance for long-term outdoor use.

Thermal Stability – Good dimensional stability and heat resistance.

Good Processability – Suitable for injection molding, extrusion, and thermoforming.

|

Property |

Test Method |

Typical Value |

|

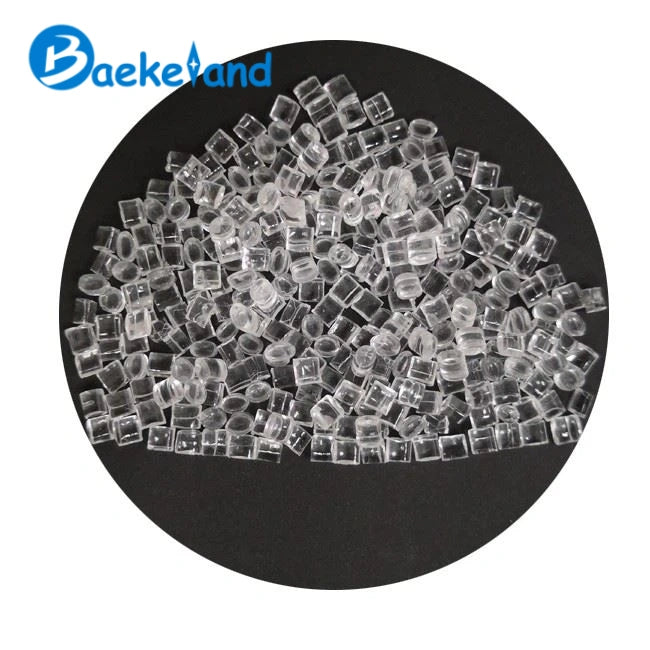

Appearance |

Visual |

Transparent Granules |

|

Density |

ASTM D792 |

1.17–1.19 g/cm³ |

|

Melt Flow Index (MFI) |

ASTM D1238 (230℃/3.8kg) |

2–10 g/10min |

|

Tensile Strength |

ASTM D638 |

≥60 MPa |

|

Elongation at Break |

ASTM D638 |

≥6% |

|

Flexural Strength |

ASTM D790 |

≥90 MPa |

|

Impact Strength (Notched Izod) |

ASTM D256 |

≥10 kJ/m² (modified type) |

|

Light Transmittance |

ASTM D1003 |

≥92% |

|

Vicat Softening Temperature |

ASTM D1525 |

105–112°C |

|

UV Resistance |

- |

Excellent |

|

Flame Rating (Optional) |

UL94 |

HB or V-2 |

Typical Applications

Automotive Parts: Rear lamps, signal covers, interior light diffusers

Lighting Components: LED light guides, lamp covers, lenses

Display & Panels: TV/Monitor screen protection, touchscreen covers

Optical Components: Lenses, diffusers, prisms

Construction Materials: Transparent sheets for signage and windows

Q1: What is the main advantage of modified PMMA over standard PMMA?

A: Modified PMMA has significantly improved impact resistance while maintaining high optical clarity, making it ideal for demanding outdoor and optical applications.

Q2: Is this PMMA suitable for outdoor use?

A: Yes. It has excellent weather resistance and UV stability, suitable for long-term outdoor exposure.

Q3: Can it be used in injection molding?

A: Absolutely. It is optimized for both injection molding and extrusion processes.

Q4: Do you provide custom formulations?

A: Yes, we offer customized solutions including UV-resistant, flame-retardant, and high-flow grades to meet specific customer requirements.

Q5: What is your MOQ and lead time?

A: MOQ is typically 1 ton. Lead time ranges from 7–15 days depending on stock and customization.